The roar of a rocket tearing through the atmosphere, pushing humanity towards the stars, is one of the most awe-inspiring sounds and sights imaginable. For decades, the heart of that power – the engines that defied gravity – beat strongest in the unassuming suburbs of Los Angeles. This is the story of Rocketdyne, a name synonymous with the golden age of space exploration, and its deep, enduring connection to Southern California. From the frantic race to the Moon to the workhorse of the Shuttle era and beyond, Rocketdyne’s innovations, forged in the San Fernando Valley, propelled not just spacecraft, but the very ambition of humankind. But the landscape of space exploration is constantly shifting. How does this legendary company’s legacy stack up against the disruptive forces of the modern New Space era, exemplified by companies like SpaceX?

From V-2 Secrets to California Sun: The Birth of a Powerhouse

The story of Rocketdyne officially begins in 1955, when it was spun off as a separate division from North American Aviation (NAA). However, its roots dig deeper, back to the final days of World War II and the dawn of the Cold War. NAA, already a major player in aircraft manufacturing, recognized the strategic importance of rocket technology, particularly the captured German V-2 missiles and the expertise of engineers like Wernher von Braun.

In 1948, NAA began testing liquid-fueled rocket engines in the then-remote Simi Hills, establishing the Santa Susana Field Laboratory (SSFL). This spraewling site, perched above the San Fernando Valley, along with the main engineering and manufacturing complex established later in Canoga Park, became the crucible where the future of American rocketry was forged. Early work focused on improving V-2 engine designs, leading to engines like the A-5 (or NAA75-110) used on the Redstone missile – the rocket that launched America’s first satellite, Explorer 1, and its first astronaut, Alan Shepard. You can almost feel the echoes of these monumental achievements when you explore LA’s hidden aerospace history.

Rocketdyne quickly moved beyond adapting existing designs. The development of the S-3D engine for the Jupiter and Thor intermediate-range ballistic missiles marked a significant step. These early successes cemented Rocketdyne’s position as the premier liquid-fuel rocket engine manufacturer in the United States, setting the stage for its most defining role.

Igniting the Moonshot: The Saturn V Engines

The Space Race, ignited by the Soviet Union’s launch of Sputnik in 1957, demanded unprecedented power. President Kennedy’s audacious goal of landing a man on the Moon before the end of the 1960s required a rocket of staggering scale: the Saturn V. And Rocketdyne was tasked with building its colossal engines.

The Mighty F-1: At the base of the Saturn V’s first stage (S-IC) sat a cluster of five F-1 engines, the most powerful single-chamber liquid-fueled rocket engines ever built and flown. Each F-1 generated a staggering 1.5 million pounds of thrust at sea level (over 7.5 million pounds total for the cluster), burning a mixture of RP-1 (a highly refined kerosene) and liquid oxygen (LOX) at an incredible rate – nearly 3 tons of propellant per second, per engine. Developed throughout the late 1950s and early 1960s, overcoming severe combustion instability problems was a monumental engineering feat achieved at the Canoga Park and Santa Susana facilities. Standing beneath a preserved F-1 engine today evokes a sense of raw, untamed power.

The Versatile J-2: Powering the Saturn V’s second stage (S-II, with five engines) and third stage (S-IVB, with one engine), was the J-2. This engine, burning ultra-cold liquid hydrogen (LH2) and LOX, was a marvel in its own right. While less powerful than the F-1 (around 230,000 pounds of thrust in vacuum), the J-2 was highly efficient and, critically, restartable in space. This restart capability was essential for the S-IVB stage to perform the trans-lunar injection burn, sending Apollo astronauts out of Earth orbit and towards the Moon. The J-2 also powered the first stage of the Saturn IB, used for early Apollo test flights and Skylab missions.

The sheer scale of the Apollo program transformed Rocketdyne and the surrounding Los Angeles communities. At its peak in the mid-1960s, Rocketdyne employed upwards of 65,000 people, turning Canoga Park into a boomtown fueled by the quest for the Moon. The intricate work of designing, building, and testing these complex machines demanded a highly skilled workforce, contributing significantly to Southern California’s identity as an aerospace hub. It’s a legacy you can still sense when you discover the birthplace of the engines that went to the moon.

The Reusable Era: Space Shuttle Main Engines (SSMEs)

Following the triumph of Apollo, NASA embarked on its next ambitious project: the Space Shuttle. This reusable spacecraft required engines unlike any before – powerful, efficient, and capable of multiple flights. Once again, Rocketdyne won the contract, delivering the RS-25 engine, better known as the Space Shuttle Main Engine (SSME).

The SSME represented a leap in complexity and performance. Burning LH2 and LOX in a sophisticated staged-combustion cycle, it achieved very high specific impulse (a measure of engine efficiency) and could throttle its thrust significantly (from 67% to 109% of its rated power level). Three SSMEs, mounted on the Orbiter’s tail, provided the main ascent thrust alongside the solid rocket boosters.

Operating at extreme pressures and temperatures (higher chamber pressure than the F-1), the SSMEs pushed the boundaries of materials science and engineering. They were designed for reuse, requiring meticulous inspection and refurbishment between each of the 135 successful Shuttle missions. Over the Shuttle program’s 30-year lifespan, the SSMEs underwent several block upgrades (Phase II, Block I, Block II) to improve reliability, safety, and performance. These engines were true thoroughbreds – high-performance, complex, and demanding, but ultimately successful in enabling routine access to low Earth orbit.

A Shifting Landscape: Mergers, Acquisitions, and Pratt & Whitney Rocketdyne

The aerospace industry is marked by cycles of expansion and consolidation. Rocketdyne, initially part of North American Aviation, became part of Rockwell International in 1967. In 1996, Boeing acquired Rockwell’s aerospace and defense divisions, including Rocketdyne.

A significant chapter began in 2005 when Boeing sold its Rocketdyne Propulsion & Power unit to United Technologies Corporation (UTC). UTC merged it with its existing Pratt & Whitney Space Propulsion division, creating Pratt & Whitney Rocketdyne (PWR). This era, lasting until 2013, saw the continuation of legacy programs like the SSME (RS-25) and the reliable RL10 upper-stage engine (originally a Pratt & Whitney design, but now part of the combined portfolio). PWR also supplied the RS-68 engine for the Delta IV rocket’s first stage and worked on advanced concepts like the J-2X engine (an evolution of the Apollo-era J-2) intended for NASA’s cancelled Constellation program. Searching for “Pratt & Whitney Rocketdyne” reveals this specific, yet crucial, period in the company’s lineage, a bridge between its Rockwell/Boeing past and its Aerojet future. You can trace the evolution of Rocketdyne’s legacy through these corporate shifts.

In 2013, UTC sold Pratt & Whitney Rocketdyne to GenCorp, which already owned another legacy rocket engine manufacturer, Aerojet. The two were combined to form Aerojet Rocketdyne, consolidating much of America’s traditional rocket propulsion expertise under one roof.

Aerojet Rocketdyne: Carrying the Torch

As Aerojet Rocketdyne, the company continued to be a critical supplier for NASA and the Department of Defense. Key programs included:

- RS-25: The inventory of flight-proven SSMEs was refurbished and upgraded to serve as the core stage engines for NASA’s Space Launch System (SLS), the massive rocket designed to return humans to the Moon under the Artemis program. New production RS-25s are also being manufactured.

- RL10: This venerable hydrogen engine, with roots stretching back to the 1960s, continues to power the upper stages of Atlas V, Delta IV Heavy, and the new Vulcan Centaur rocket, as well as the SLS Interim Cryogenic Propulsion Stage. Future SLS variants will use an advanced Exploration Upper Stage powered by four RL10s.

- RS-68: The main engine for the Delta IV Heavy rocket.

- Defense Programs: Providing propulsion for a wide array of missile defense systems (like THAAD and Standard Missile), tactical missiles (like Javelin and Stinger), and strategic deterrents. Aerojet Rocketdyne is a major producer of solid rocket motors, primarily at its Camden, Arkansas facility.

- In-Space Propulsion: Developing advanced electric propulsion systems (like those used on the Gateway lunar outpost) and reaction control thrusters for spacecraft.

The Los Angeles Legacy Endures

While production has diversified and facilities exist in other states (like Florida, Arkansas, and Alabama), the ghost of Rocketdyne looms large over Los Angeles. The Canoga Park facility remains a hub of engineering talent, even as the nearby Santa Susana Field Lab undergoes a complex, decades-long environmental cleanup process resulting from its early nuclear and chemical research activities.

The impact on the region extends beyond the factory gates. Rocketdyne fostered generations of engineers, technicians, and support staff, creating a unique ecosystem of aerospace expertise in Southern California. It attracted talent from across the country and the world, contributing to the diverse fabric of Los Angeles. The company’s success fueled local economies and inspired countless students to pursue careers in science and technology. This deep connection is a vital part of the journey through Southern California’s aerospace heritage.

Engines of Change: Rocketdyne vs. SpaceX?

The rise of “New Space” companies, particularly SpaceX, has dramatically altered the launch landscape, inevitably leading to comparisons like “Pratt & Whitney Rocketdyne vs SpaceX” or “Aerojet Rocketdyne vs SpaceX.” However, this isn’t a simple head-to-head competition; it’s more a reflection of different eras, philosophies, and business models.

Legacy Aerospace (Rocketdyne/Aerojet Rocketdyne/L3Harris):

- Model: Traditionally reliant on government contracts (NASA, DoD), often cost-plus, emphasizing extremely high reliability and performance verified through extensive ground testing before first flight.

- Engines: Highly complex, high-performance engines optimized for specific missions (e.g., SSME/RS-25, RL10). Often bespoke, with lower production rates. Reusability was achieved with the SSME, but at significant refurbishment cost.

- Strengths: Decades of proven flight heritage, deep expertise in complex propulsion systems (staged combustion, hydrogen), crucial supplier for national security and flagship exploration missions (SLS).

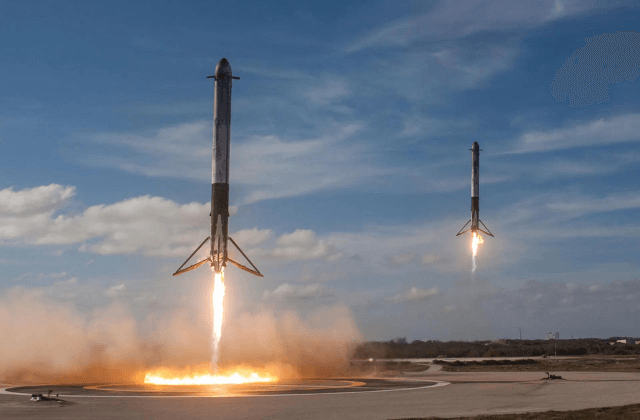

New Space (SpaceX):

- Model: Vertically integrated, focused on lowering launch costs through mass production and aggressive reuse. Leverages commercial market demand alongside government contracts. Embraces iterative design and flight testing (“build, fly, fail, fix”).

- Engines: Simpler, gas-generator cycle engines (Merlin for Falcon 9) designed for mass production and reliability through redundancy. More advanced full-flow staged combustion methalox engine (Raptor for Starship) also designed for high production rates and rapid reuse.

- Strengths: Dramatically reduced launch costs, rapid launch cadence, demonstrated orbital-class booster reusability, driving innovation in launch market dynamics.

The Comparison: It’s less “vs.” and more “and.” SpaceX’s Merlin engine, while reliable and cost-effective, doesn’t match the sheer performance (specific impulse) of the hydrogen-fueled RS-25 or RL10. However, SpaceX achieves mission goals through vehicle architecture (more engines, larger stages) and accepts lower per-engine performance for massive cost savings and reusability. Raptor represents a step towards higher performance comparable to legacy staged-combustion engines, but with a focus on mass manufacturability unknown in the Shuttle era.

Aerojet Rocketdyne (now part of L3Harris) continues to provide essential, high-performance propulsion systems that SpaceX currently does not, particularly for deep space exploration (hydrogen upper stages like Centaur and EUS) and critical defense applications. SpaceX, meanwhile, has revolutionized access to orbit and is pushing the envelope on fully reusable launch systems with Starship. Both play vital, albeit different, roles in the current space ecosystem.

The Next Chapter: L3Harris Technologies

In July 2023, another major shift occurred: L3Harris Technologies completed its acquisition of Aerojet Rocketdyne for $4.7 billion. L3Harris, a large defense contractor, views the acquisition as a way to strengthen its position in missile defense, hypersonics, and space domains, ensuring a robust domestic supplier for critical propulsion technologies. The integration aims to leverage L3Harris’s resources to enhance production efficiency and accelerate innovation within the former Aerojet Rocketdyne segment, now operating as an L3Harris business unit.

An Undeniable Impact

From the thunderous liftoffs of Saturn V rockets carrying astronauts to the Moon, powered by the F-1 and J-2, to the reliable workhorse SSMEs enabling the construction of the International Space Station, the engines born in Rocketdyne’s Los Angeles facilities have left an indelible mark on history. The company, evolving through North American Aviation, Rockwell, Boeing, Pratt & Whitney Rocketdyne, Aerojet Rocketdyne, and now L3Harris, embodies the evolution of the American aerospace industry.

While the landscape now includes dynamic players like SpaceX fundamentally changing the economics of launch, the legacy of Rocketdyne endures. Its technological achievements remain benchmarks, and its current iteration continues to provide the power for America’s most critical space and defense missions. The story of Rocketdyne is intrinsically linked to the story of Los Angeles – a tale of innovation, ambition, and reaching for the stars, born under the California sun. It’s an epic saga best understood when you experience the epic story of LA space innovation firsthand. The engines have changed, the companies have merged, but the drive to explore, powered by incredible feats of engineering, continues.

by xotatech.com

by xotatech.com