The ochre plains and towering volcanoes of Mars have captivated human imagination for centuries. Once the realm of science fiction, the prospect of sending humans to walk, live, and work on the Red Planet is rapidly transitioning into the domain of engineering reality. At the forefront of this monumental push is SpaceX, the aerospace company founded by Elon Musk with the explicit goal of making humanity multiplanetary. Their chosen chariot? Starship, a colossal, fully reusable rocket system designed not just to reach Mars, but to build a sustainable city there. While the towering steel prototypes are assembled and tested under the Texas sun at Starbase, the intricate design, complex mission architecture, and the very blueprint for this interplanetary future are being forged within the minds and computers of SpaceX’s headquarters in Hawthorne, a city nestled within the sprawling aerospace hub of Los Angeles County. This is where the “braintrust” resides, meticulously crafting the roadmap for the first human mission to Mars.

The Martian Imperative: Why Embark on Such a Journey?

Before delving into the “how,” it’s worth revisiting the “why.” Why Mars? The motivations are manifold, ranging from the deeply scientific to the profoundly existential. Mars holds invaluable clues about planetary formation, the potential for past or present life, and the history of our solar system. Establishing a presence there offers unparalleled opportunities for geological research, atmospheric studies, and astrobiology.

Beyond pure science, there’s the powerful argument for redundancy. As Stephen Hawking and others have warned, concentrating humanity on a single planet leaves us vulnerable to existential threats, whether asteroid impacts, pandemics, or self-inflicted catastrophes. Establishing a self-sustaining outpost on another world is arguably the ultimate insurance policy for the long-term survival of human consciousness. It represents securing humanity’s multiplanetary future, a crucial step in our cosmic evolution.

Furthermore, the sheer challenge of reaching and inhabiting Mars acts as a powerful technological catalyst. The problems that must be solved – from closed-loop life support and radiation shielding to advanced propulsion and in-situ resource utilization – will drive innovation with potential benefits back on Earth. And, undeniably, there’s the innate human spirit of exploration, the drive to push boundaries and venture into the unknown.

However, the challenges are immense. Mars is tens of millions of miles away, requiring journeys lasting 6-9 months each way. Crews face prolonged exposure to deep space radiation, the physiological effects of microgravity (or partial gravity on Mars, which is about 38% of Earth’s), the psychological strains of isolation, and complete reliance on complex life support systems. Landing massive payloads on a planet with a thin atmosphere is notoriously difficult, and establishing a self-sufficient base requires unprecedented logistical and engineering prowess. It’s precisely these hurdles that necessitate a vehicle as ambitious as Starship.

Starship: The Colossus Designed for Mars

SpaceX’s answer to the Mars challenge is Starship, a two-stage, fully reusable launch system poised to become the most powerful rocket ever built. It consists of the Super Heavy booster (the first stage) and the Starship spacecraft (the second stage, which also serves as the crew/cargo transport).

Several key design philosophies, largely iterated and refined at the Hawthorne headquarters, make Starship uniquely suited for ambitious interplanetary missions:

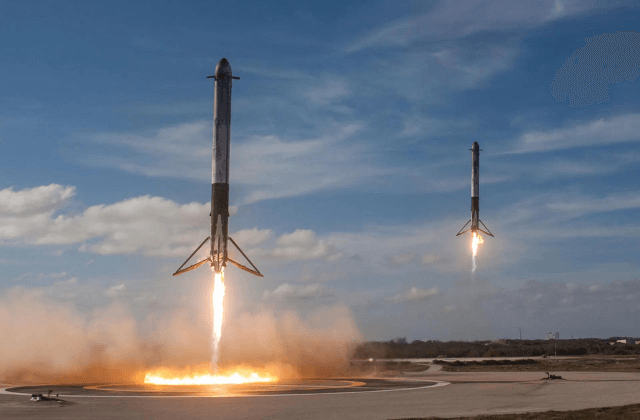

- Full Reusability: Unlike traditional rockets where expensive upper stages are discarded, both Super Heavy and Starship are designed for rapid reuse. Super Heavy aims to return to the launch site for a tower catch, while Starship re-enters Earth’s atmosphere and lands propulsively. This airline-like approach drastically reduces the cost per launch, a fundamental requirement for affordable Mars colonization.

- Massive Payload Capacity: Starship is designed to lift over 100 metric tons (and potentially up to 150 tons or more) to low Earth orbit (LEO) in its reusable configuration. This enormous capacity is essential for transporting the large habitats, power systems, ISRU equipment, supplies, and eventually, dozens of people needed for a Martian settlement in a single launch.

- Raptor Engines: Both stages are powered by SpaceX’s advanced Raptor engines, which burn cryogenic liquid methane (CH4) and liquid oxygen (LOX). Methane was chosen strategically because it can theoretically be synthesized on Mars using atmospheric carbon dioxide and subsurface water ice via the Sabatier reaction – a cornerstone of SpaceX’s plan for return journeys. Raptors utilize a highly efficient full-flow staged combustion cycle, providing immense thrust.

- Stainless Steel Construction: Departing from the carbon composites initially envisioned (and used in Falcon 9 fairings), Starship’s primary structure is made of stainless steel alloys. While heavier, steel is inexpensive, relatively easy to manufacture and repair, and performs exceptionally well at both the cryogenic temperatures of its propellants and the high temperatures of atmospheric reentry.

- Orbital Refueling: Perhaps the most critical architectural element for Mars missions is orbital refueling. A single Starship launch doesn’t carry enough propellant to send 100+ tons all the way to Mars. The plan involves launching a fully-fueled Starship (carrying crew or cargo) into LEO, followed by several launches of dedicated Starship “tanker” variants. These tankers rendezvous with the primary Starship and transfer propellant in orbit, fully topping off its tanks for the long interplanetary journey. This architecture leverages the low launch cost enabled by reusability to assemble the necessary delta-v (change in velocity) in orbit, enabling massive payloads to reach Mars.

This entire SpaceX’s groundbreaking launch vehicle concept, from engine design nuances to structural materials choices and the complex orbital dance of refueling, originates from the engineering powerhouse in Southern California.

Hawthorne: The Crucible of Martian Dreams

While Starbase in South Texas is the public face of Starship development – the place of spectacular launches, rapid prototyping, and dramatic tests – SpaceX’s headquarters at 1 Rocket Road, Hawthorne, CA, is the strategic mind behind the metal. It’s here that the fundamental design work, the intricate mission planning, the complex software development, and the relentless engineering problem-solving take place.

Think of Hawthorne as the central nervous system. It houses thousands of engineers, designers, analysts, and technicians collaborating across disciplines. While Texas builds and breaks hardware based on these designs, the Hawthorne teams are constantly:

- Designing and Iterating: Using advanced Computer-Aided Design (CAD) and simulation software, engineers model every aspect of the Starship system – from the thrust structure of the Super Heavy booster, capable of handling the force of 33 Raptor engines, to the aerodynamic performance of Starship’s flaps during atmospheric entry, to the plumbing intricacies of the propellant transfer systems. Data from Starbase tests feeds directly back into this design loop, leading to rapid iterations and improvements.

- Developing Avionics and Software: The complex guidance, navigation, and control (GNC) systems needed to launch, maneuver, rendezvous, land, and relaunch Starship are developed and rigorously tested in Hawthorne. This includes the software that will autonomously dock tankers in orbit, calculate landing trajectories on two different planets, and manage the vehicle’s health.

- Engineering Life Support: Designing the Environmental Control and Life Support Systems (ECLSS) for a long-duration Mars mission is a monumental task. Hawthorne engineers work on closed-loop systems to recycle air and water, manage waste, grow food, and maintain a habitable environment within Starship for months, potentially years. This is far more complex than the systems used for the relatively short trips to the International Space Station.

- Mission Architecture & Planning: The entire sequence of a Mars mission – launch cadence, orbital mechanics for tanker rendezvous, Trans-Mars Injection (TMI) burns, trajectory optimization, Mars atmospheric entry profiles, landing site selection criteria, surface operation strategies, ISRU process scaling, and return journey planning – is meticulously modeled and simulated by mission architects in Hawthorne. They create the blueprint for interplanetary travel.

- Structural and Thermal Analysis: Ensuring the massive steel structure can withstand the incredible forces of launch, the vacuum of space, the cryogenic temperatures of propellants, and the fiery heat of reentry on both Earth and Mars requires sophisticated analysis. Finite element analysis (FEA) and computational fluid dynamics (CFD) are constantly run on powerful computer clusters in this aerospace engineering hub in California.

Hawthorne isn’t just designing a rocket; it’s designing a transportation system capable of opening up the solar system, with Mars as the primary initial destination.

The Grand Architecture: Charting the Path to Mars

The SpaceX Mars mission architecture, conceived and refined in Hawthorne, is audacious in its scale and reliance on Starship’s unique capabilities:

- Launch and Ascent: A Starship (carrying crew or cargo for Mars) launches atop a Super Heavy booster from Earth. After stage separation, Super Heavy performs a boostback burn and returns for landing near the launch site.

- Orbital Refueling: The Starship spacecraft reaches LEO but lacks the fuel for the Mars trip. Over the following days or weeks, multiple Starship tankers launch, rendezvous with the primary Starship, and transfer potentially over 1,000 metric tons of methane and liquid oxygen. This is the linchpin enabling heavy cargo delivery to Mars. Each tanker then returns to Earth to be refueled and reused.

- Trans-Mars Injection (TMI): Once fully fueled, the Mars-bound Starship fires its Raptor engines for a final time in Earth orbit, accelerating onto a trajectory towards Mars.

- Interplanetary Coast: The journey takes approximately 6 to 9 months, depending on the relative positions of Earth and Mars during the specific launch window (which occurs roughly every 26 months). During this time, the crew relies entirely on the ship’s life support systems and radiation shielding.

- Mars Entry, Descent, and Landing (EDL): Approaching Mars, Starship performs an atmospheric entry maneuver, using its heat shield and large flaps to decelerate aerodynamically in the thin Martian atmosphere. The final descent and landing are achieved propulsively, using the Raptor engines for a soft, vertical touchdown – a significant challenge given Starship’s enormous size (landing a vehicle potentially weighing 200 metric tons or more is orders of magnitude beyond anything landed on Mars previously). Understanding the complexities of landing on another planet is paramount.

- Surface Operations & ISRU: Early missions will focus on establishing basic infrastructure – habitats, power generation (likely solar), and crucially, the In-Situ Resource Utilization (ISRU) plant. This plant will extract water ice from beneath the Martian surface and harvest carbon dioxide from the atmosphere. Using electrolysis to split water into hydrogen and oxygen, and then the Sabatier process to combine hydrogen with CO2, the plant will produce liquid methane (CH4) fuel and liquid oxygen (O2) oxidizer – the very propellants Starship needs for the return trip. This eliminates the need to carry return fuel all the way from Earth, dramatically improving mission mass efficiency. Automating and validating this ISRU process on Mars is perhaps the biggest technological hurdle after landing itself.

- Mars Ascent and Return: Once enough propellant (~1,200 metric tons per ship) has been produced and stored, the crew boards Starship. The Raptor engines ignite, lifting the spacecraft directly off the Martian surface and onto a trajectory back to Earth.

- Earth Return and Landing: After another months-long coast, Starship performs a final atmospheric entry and propulsive landing back on Earth, completing the round trip.

Every single phase of this complex sequence, from the launch cadence calculations to the propellant production rates required on Mars, is being meticulously planned and simulated by the teams charting the course for a human mission to Mars in Hawthorne.

Tackling the Unprecedented Challenges

The path to Mars is fraught with technical difficulties, and the Hawthorne braintrust is tasked with finding solutions:

- Life Support Reliability: Closed-loop systems must function flawlessly for years, far from any resupply possibility. Designing robust, fault-tolerant systems for air revitalization, water purification, temperature control, and waste management is critical. Redundancy is key.

- Radiation Protection: Deep space is filled with galactic cosmic rays (GCRs) and occasional solar particle events (SPEs), posing significant health risks to astronauts. Engineers are designing shielding strategies (potentially using water tanks or the ship’s own propellant) and researching operational procedures to minimize exposure during the long transit and on the Martian surface, which lacks a strong global magnetic field like Earth’s.

- Landing the Behemoth: Safely landing a vehicle the size and mass of Starship on Mars using propulsive descent is an unprecedented challenge. The GNC software must be incredibly precise, accounting for the thin atmosphere, potential dust storms, and engine performance variations. Extensive simulations and potentially scaled robotic precursor missions will be needed to validate the approach.

- ISRU Validation: While the chemistry is understood (MOXIE on NASA’s Perseverance rover successfully produced oxygen from Martian CO2), scaling up an autonomous plant on Mars capable of mining water ice and producing hundreds of tons of cryogenic propellants reliably is a massive undertaking. Designing, building, deploying, and verifying this technology remotely is a primary focus.

- Human Factors: Beyond the core engineering, Hawthorne teams consider the psychological well-being of the crew. Designing habitable volumes, managing crew workload, ensuring adequate recreation and communication, and planning for potential medical emergencies during years-long missions are vital components of mission success. Finding engineering solutions for deep space travel encompasses both hardware and human needs.

The Road Ahead: From L.A. Designs to Martian Footprints

SpaceX continues its rapid iterative development of Starship, with ongoing flight tests from Starbase pushing the vehicle closer to operational status. While timelines are ambitious and subject to change – Elon Musk has suggested uncrewed missions could head towards Mars within the next few years, potentially paving the way for human landings around 2029 or 2031 – the direction is clear.

The dream of planting human footprints, and eventually settlements, on Mars is no longer confined to fantasy. It is being actively engineered, simulated, and planned, piece by painstaking piece. And while the rockets rise from the Texas coast, the intellectual heart of this grand endeavor beats strongly in Los Angeles. The journey beyond Earth, the complex choreography of sending Starships to Mars and establishing a human presence there, is being meticulously designed today by the braintrust in Hawthorne. They are not just building a rocket; they are architecting humanity’s next giant leap. As Starship development progresses, we are getting ever closer to being able to explore the future of spaceflight and witness the dawn of our multiplanetary age.

by xotatech.com

by xotatech.com